Project Overview

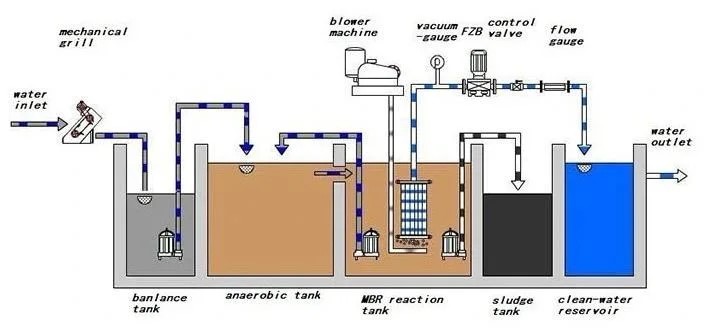

- MBR system is a biological reactor, which is similar to conventional activated sludge processes. In this reactor, microorganisms (bacteria and other microbes) break down organic matter and pollutants in the wastewater through biological degradation.

- MBR technology is the use of membrane filtration as a solid-liquid separation step. These membranes are typically made of polymeric materials such as polyethylene, polypropylene, or polyvinylidene fluoride (PVDF). They come in various configurations, including flat sheet and hollow fiber.

- To maintain optimal conditions for microbial activity, MBR systems use an aeration system to supply oxygen to the microorganisms in the reactor. This ensures efficient biological treatment of the wastewater.

How Membrane Bioreactors Work:

- Wastewater Treatment: Raw wastewater is introduced into the biological reactor, where microorganisms break down organic pollutants and contaminants. This biological treatment step is similar to conventional activated sludge processes.

- Solid-Liquid Separation: Instead of using settling tanks to separate biomass (microorganisms) from treated water, MBRs employ membrane filtration. The membranes act as physical barriers, allowing only clean water to pass through while retaining suspended solids, bacteria, and contaminants.

Get a Quote

Get a Quote